Intelligent Environmental Protection

Construction Site Volatile Gas Detection Service

A construction engineering department used drones to detect volatile organic compounds at a construction site, focusing on gas emissions from the site and dump trucks. After the service was completed, the management personnel immediately received a data analysis report, ensuring that the construction site's volatile gases were non-toxic.

Industrial Zone Gas Emission Detection Service

The Environmental Protection Bureau used a drone service solution to focus on detecting gases emitted from chemical plants in industrial zones. Using gas detectors mounted on drones, they quickly detected and analyzed the gas content of the factory chimneys, identified pollutants, established a ledger, and created pollution heat maps.

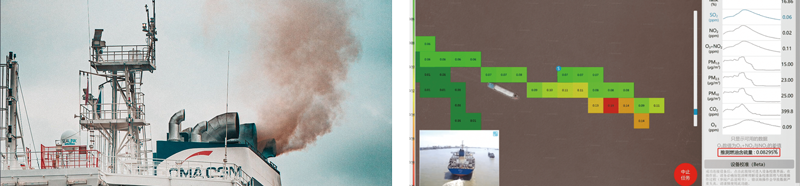

● Ship Exhaust Gas Detection Service

A maritime bureau monitored ship exhaust gases, monitoring more than ten ships at berth. Through real-time visualization analysis in the backend, it was automatically calculated that the fuel sulfur content of a certain ocean-going vessel exceeded 0.5% m/m, which can be used as a key inspection target for further on-site spot checks and laboratory testing.

● Solution Value

☆ Comprehensive monitoring, reducing monitoring difficulty, increasing monitoring range, and avoiding blind spots in random checks;

☆ Gas emission distribution is clear at a glance, quickly locating pollution sources;

☆ Improve patrol efficiency and ensure detection without blind spots;

☆ Fully grasp the environmental situation and eliminate pollution risks in time;

☆ The three-dimensional perspective provides visual decision-making basis for rectification work;

☆ Significantly reduce investment costs and improve supervision efficiency;

● Smart Public Security Solution

|

|

|

|

|

| Flight Platform | Emergency Monitoring | Emergency Loudspeaker | Emergency Drop | Intelligent system platform |

Smart Environmental Protection - Drone Water Supply Company Inspection Solution

● Regular Inspection | Inspection Content

Water source and reservoir inspection: water quality and water level monitoring, dam safety inspection, complex terrain coverage inspection, etc.

Water plant and pipe network facilities inspection: monitoring the operation status of facilities, night and hazardous area operations (drone infrared detection), etc.

Emergency response and law enforcement support: handling emergencies (post-disaster inspection), law enforcement evidence collection (sewage discharge), etc.

● Regular Inspection | Equipment Configuration

I. Platform Construction

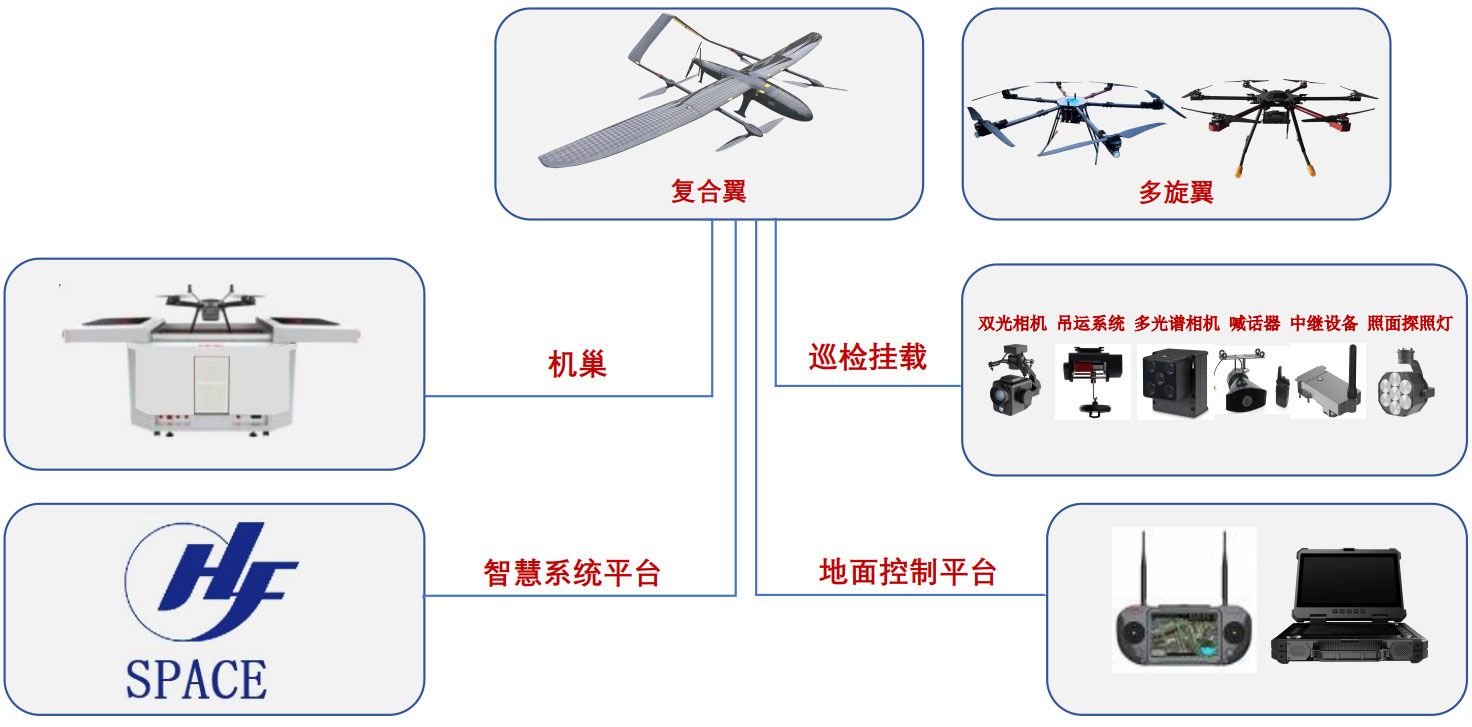

This system mainly includes AI video intelligent analysis system (developing AI model library, automatically identifying crack width, rust area and other parameters, quantifying damage, etc.), mobile video management and analysis, UAV video management and analysis by road section, and radar data intelligent analysis. Through the construction of a command wisdom platform, task setting, route planning, automatic identification, risk warning data storage and processing, pipeline facility inspection, emergency command, and illegal evidence collection are realized.

II. BIM Information Input

Using a modular architecture, a basic application support platform is built, including BIM models, GIS data, BIM+GIS engine, BPM process engine, BI analysis tools, integrated communication system, unified identity authentication service, digital twin engine, simulation decision-making engine, vehicle-road collaboration engine, Beidou high-precision positioning service, and mobile APP, providing support for various businesses in Saas (business application layer).

III. UAV + Nest

Smart Environmental Protection - Gas Pipeline Inspection Solution

Needs Analysis

● Regular Inspection | Basic Situation

Pipeline length: approximately 207 kilometers

Inspection scope: gas stations and pipelines

On-site situation: A valve chamber is set up every 20 kilometers on site, and a boundary alarm system and leakage alarm have been installed.

Inspection content: Third-party damage, leakage detection

① Man-made damage; ② Geological hazard impact; ③ Construction damage; ④ Construction damage;

● Fixed-point monitoring | Basic Situation

Monitoring points: 2 gas transmission stations, 9 valve chambers (already equipped with boundary detection and leakage detection, only data access is needed), 12 geological hazard points, 4 high-consequence areas (require fixed-point monitoring of displacement, cracking, settlement and other geological hazard risks and data access)

● Inspection Object | Hazard Analysis

| Serial Number | Target Name | Characteristic Description | Identification Requirements | |

| 1 | 1.1 | Crude oil/refined oil leakage | Oil stains on the ground around the pipeline, oil slicks on the water surface, fire above the pipeline, withered plants, oil and gas accumulation | Immediately |

| 1.2 | Natural gas leakage | Withered plants around, bubbles on the water surface above the pipeline | Immediately | |

| 2 | 2.1 | Oil theft by drilling is being implemented | Nighttime, personnel and vehicle activities around the pipeline | Immediately |

| 2.2 | Signs of oil theft by drilling | Nighttime: signs of artificial excavation and backfilling; Daytime: changes in the topography above the pipeline, soil changes, vegetation damage, leftover tools, etc. | Immediately | |

| 3 | 3.1 | New construction, reconstruction, and expansion of highways and railways | This construction generally involves prior contact to prevent construction without supervision. | Immediately |

| 3.2 | Dredging and sand mining in rivers and canals | Occurs at locations where pipelines cross rivers and canals, involving artificial or mechanical excavation and sand mining activities. | Immediately | |

| 3.3 | Mechanical excavation activities | Activities such as digging sand and soil, planting and removing trees, digging ditches, rotary tilling, and land leveling on both sides of the pipeline, and drilling activities | Immediately | |

| 3.4 | Blasting activities | Underwater blasting, quarry blasting, etc. | Immediately | |

| 3.5 | Directional drilling | Directional drilling construction of power lines, optical cables, and other pipelines | Immediately | |

| 3.6 | Manual operation | Manual excavation using shovels and picks directly above the pipeline | Immediately | |

| 4 | 4.1 | Exposed pipe, suspended | Insufficient pipeline burial depth, exposed on the surface, exposed pipelines or optical cables, suspended pipelines at the crossing of ditches | Can be delayed |

| 4.2 | Damage to water conservancy protection facilities | Damage to water conservancy facilities such as slope protection, retaining walls, and cofferdams | Can be delayed | |

| 4.3 | Landslide | Displacement of the slope where the pipeline passes | Can be delayed | |

| 4.4 | Ground subsidence | Ground subsidence along the pipeline route | Can be delayed | |

| 4.5 | Erosion | Undercutting of the soil layer above or upstream and downstream of the pipeline, resulting in insufficient burial depth | Can be delayed | |

| 5 | 5.1 | Three pile integrity check | Check for pile tilting and damage | Can be delayed |

| 5.2 | Occupation, encroachment | Prohibited items within a 5-meter range on each side | Can be delayed | |

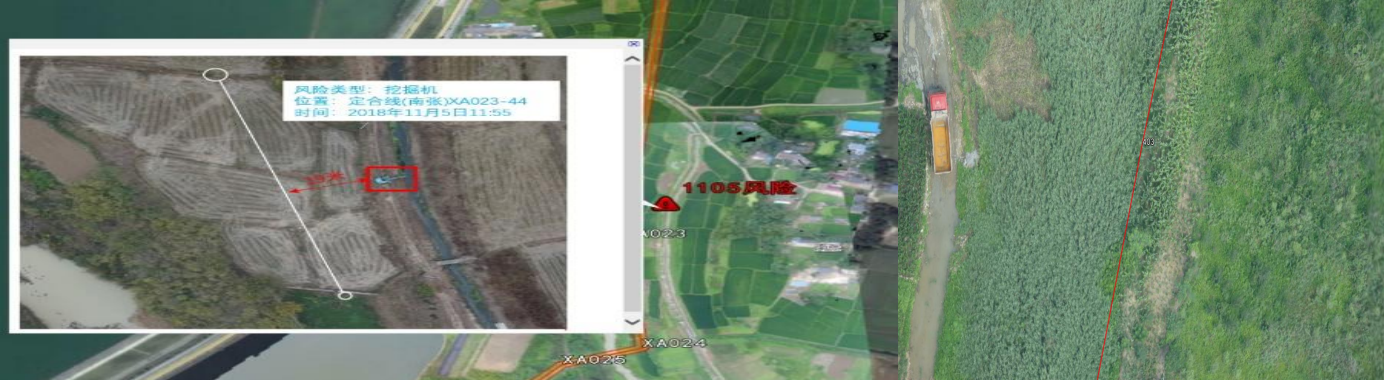

● Inspection Object | Third-party damage

|

|

|

|

|

| Third-party construction | Geological disaster | Illegal occupation | Gas theft | Drilling and stealing gas |

● Inspection Object | Current Security Situation

Manual inspection: Poor security effect, low efficiency, high risk

● Manual pipeline walking inspection faces blind spots due to the complex humanistic and geographical environment around the pipeline network;

● Manual pipeline walking inspection is limited by pipeline laying conditions. In typical sections such as river crossings and crossings, steep slopes make manual line inspection difficult, often requiring a detour of 1 to 2 kilometers to inspect a crossing pipeline, or even making it impossible to reach;

● It is difficult to identify geological disaster points during manual inspection. Usually, the manual inspection range is only about 10 meters from the pipeline centerline, while the triggering points of geological disasters often exceed this range.

● Inspection Comparison | Current Security Situation

Characteristics of traditional manual inspection methods:

(1) High cost, low efficiency.

Pipelines are mostly distributed in areas with complex terrain and poor transportation conditions. Traditional manual inspection methods are harsh, have low efficiency, high manpower requirements, long inspection time, and low effectiveness.

(2) Difficult to reach areas with complex terrain.

Because most pipelines are distributed in the wild, usually crossing multiple terrains with poor transportation conditions, traditional manual inspection methods are easily affected by heavy rain and snow, with high manpower requirements, long inspection time.

(3) Personnel safety is difficult to guarantee.

Pipeline routes are complex, such as rivers, swamps, steep slopes, etc., manual inspection is prone to personnel injury accidents.

(4) Lack of data recording in inspection activities.

Manual inspection relies on human eyes and memory, lacks data records, has poor ground photo perspectives, and cannot perform historical review and analysis.

Characteristics of UAV inspection methods:

(1) Low comprehensive cost, high efficiency.

The built-in line protection and redundancy technologies in UAVs make the UAV flight more stable and safe, capable of handling long-distance flight missions of 100 kilometers. UAVs can cruise autonomously, achieving high efficiency; UAVs can carry various payloads, and can be used for multiple purposes based on task characteristics, resulting in low comprehensive costs.

(2) Good observation range, suitable for various complex terrains.

Aerial photography from 200-300 meters above ground by UAVs offers a very good field of vision. Complex terrains such as rivers, swamps, and steep slopes have no impact on UAV flight.

(3) Low HR input.

UAVs have a high degree of automation, enabling one-button take-off and landing and automatic warnings. Personnel only need to observe at the monitoring site, which helps in the rational optimization of HR, reducing employee workload and work-related injury risks.

(4) Full record of inspection data.

UAV inspection images and data are stored in the cloud server, facilitating historical review and big data analysis.

Solution

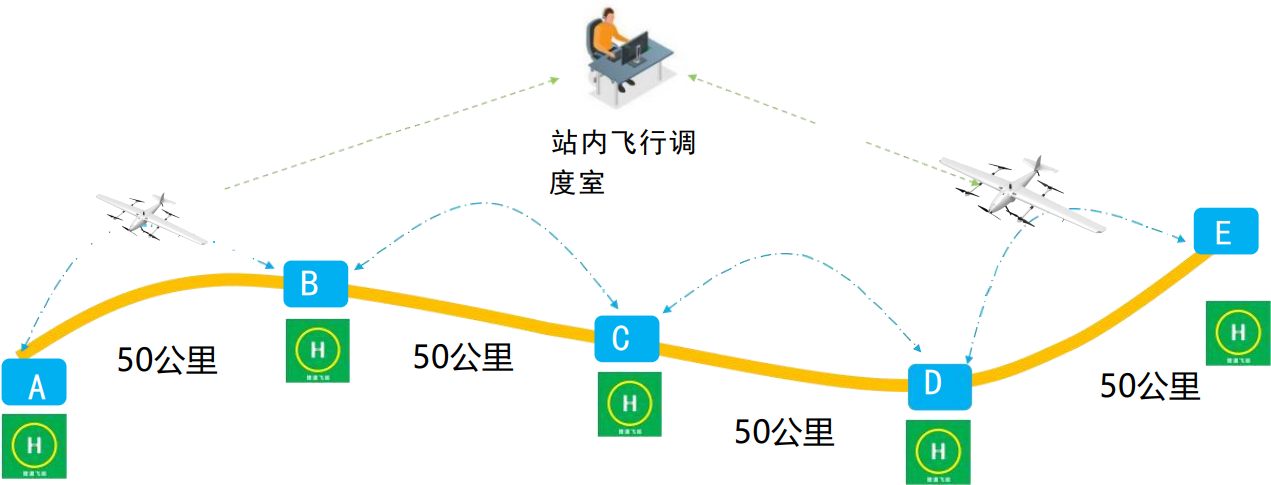

● Gas pipeline inspection | Conventional inspection mode

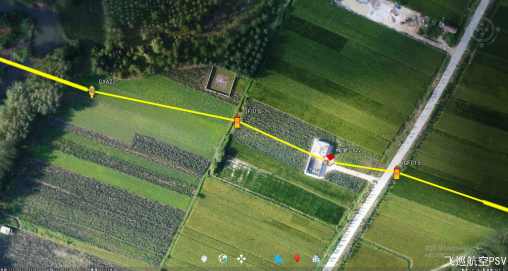

Using a leapfrog inspection mode, more than 1000 kilometers of lines can be inspected daily. In mountainous and desert areas without a 4G network, a 2.4G or 5.8G radio image transmission and data transmission link can be used to control the aircraft, greatly improving inspection efficiency. The situation around the pipeline can be viewed daily through the visualization platform. In the absence of a 4G network, the UAV inspection mode generally uses a ground station control system + UAV + high-definition camera + GPS positioning system. Through the UAV ground station system, a flight path is planned above the pipeline. The UAV will automatically fly above the pipeline. During the flight, the high-definition camera will automatically take pictures and record GPS coordinate information. After identifying problems and risks through the photos, the GPS coordinates are located in real-time, allowing for quick arrival at the site.

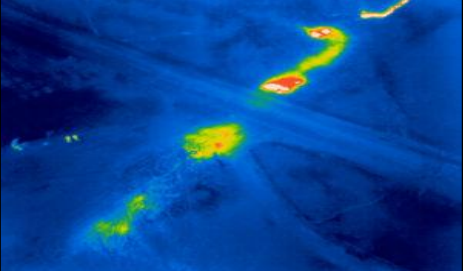

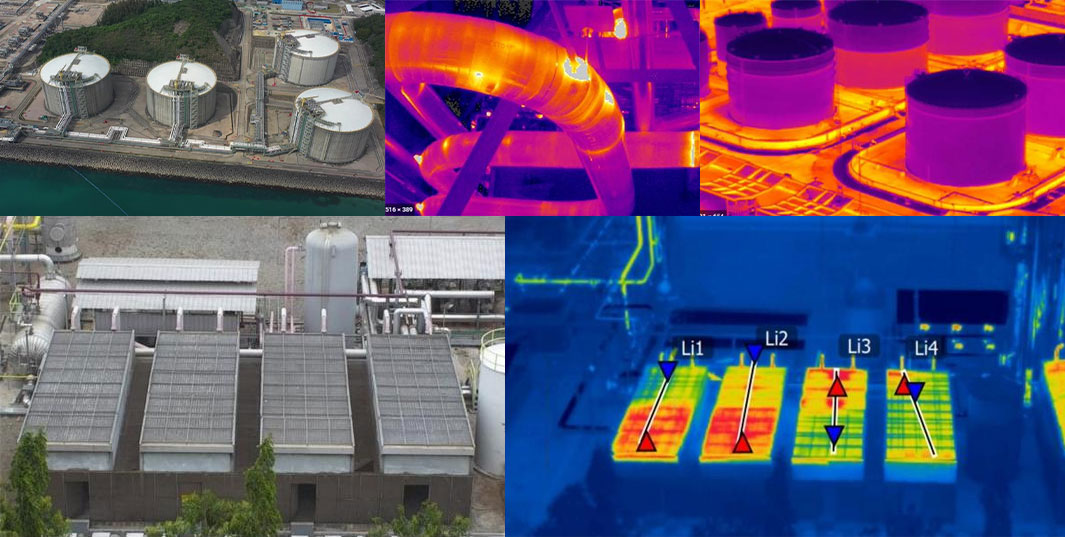

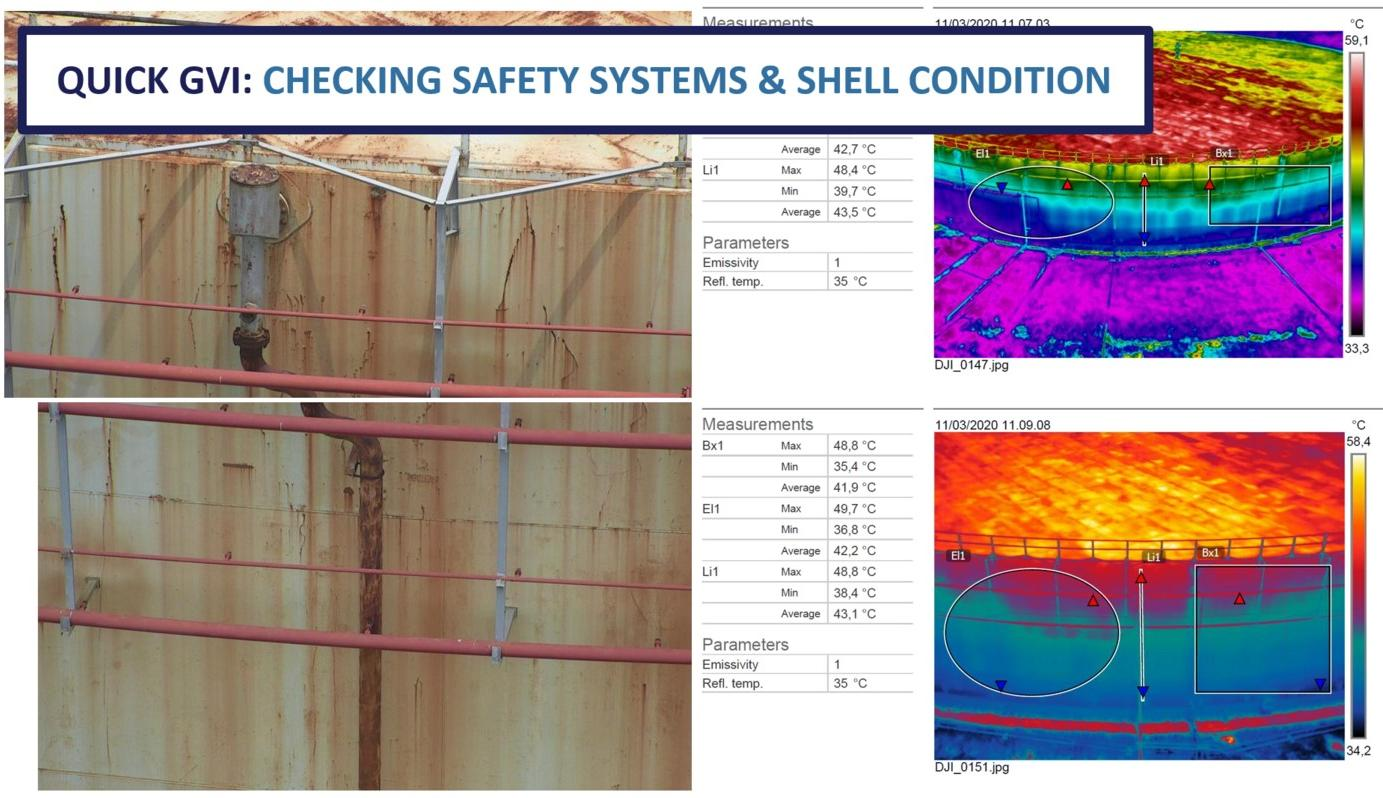

Thermal imaging leak detection:At night, UAVs can carry thermal imaging cameras to inspect pipeline leaks and patrol areas where holes are drilled for oil theft.

Long-range fixed-wing inspection:The collected high-definition photos have a resolution of up to 36 million pixels, with rich details of ground targets. The photos also include high-precision BeiDou coordinate information, allowing for precise positioning and ranging of risk targets in the photos later on.

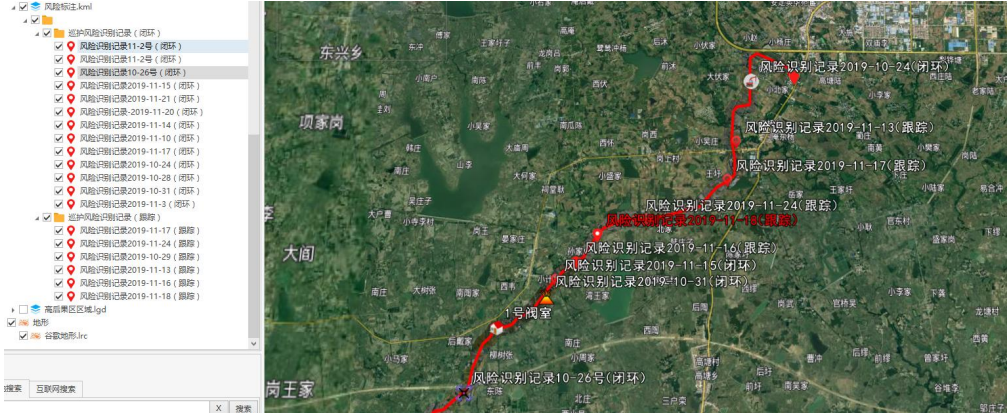

● Gas Pipeline Inspection | Inspection Analysis

☆ Analysis and statistics of inspection process data and risk data (inspection results)

Inspection operation data is stored in the inspection business database and can be retrieved, queried, and statistically analyzed; risks discovered during daily pipeline patrols and various hazard information provided by informants are displayed and dynamically tracked on the visualization platform, achieving refined management;

Inspection process data and risk data are analyzed using big data intelligent algorithms to summarize the patterns of risk occurrences at different inspection times, different locations, and different cycles, laying the data foundation for proactive risk prevention and control.

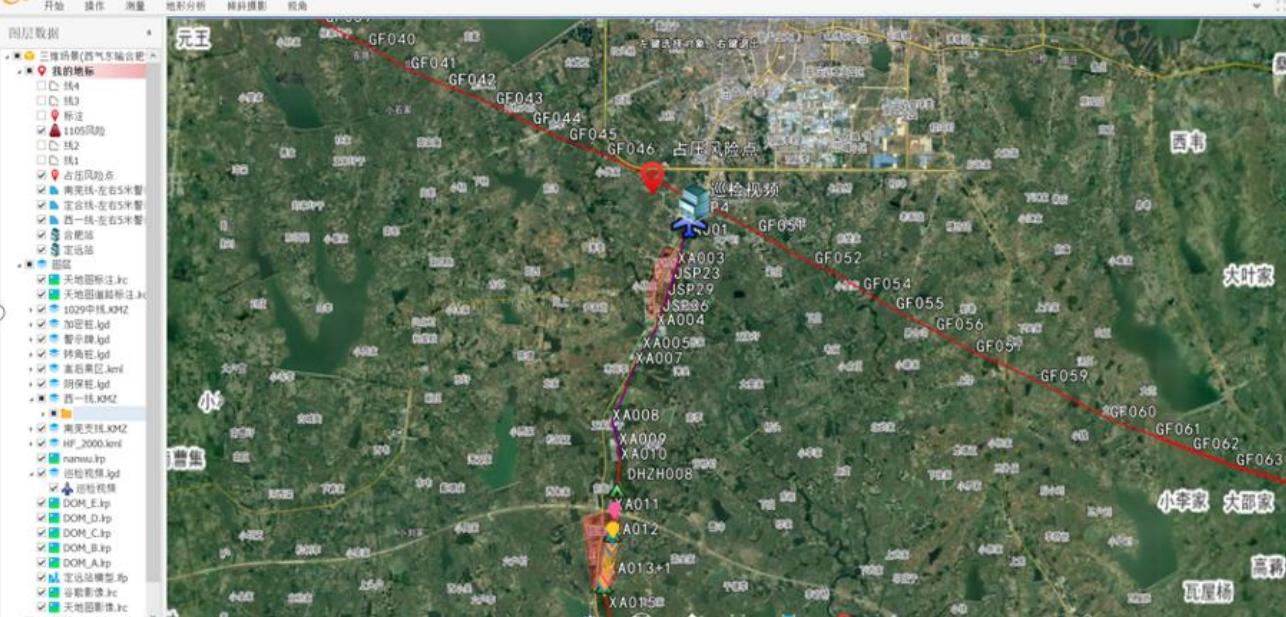

● Gas Pipeline Inspection | Software System

☆ Pipeline Safety Visualization Management Platform (PSV)

☆ Unified Presentation of All Elements

Supports the presentation of various elements such as orthophotos, oblique photography 3D models, vectors, and point clouds on the same platform.

|

|

| Background Control | Risk Marking |

● Gas Pipeline Inspection | Collected Data Results

◆ High-Definition Materials

◆ Photos with Coordinate Information

◆ Precise Location of Risk Points (Focusing on identifying directional drilling and other third-party construction)

◆ Easy to Trace Back

● Gas Pipeline Inspection | Oil Tank Corrosion Thermal Imaging Detection

● Gas Pipeline Inspection | Oil Tank Corrosion Thermal Imaging Detection

● Gas Pipeline Inspection | Pipeline Orthophotography and 3D Modeling

• Drones conduct orthophotography of the pipeline route twice a year, facilitating the analysis of changes in the surrounding environment and topographic data.

• Orthophotos are remote sensing images with orthographic projection properties. Orthophotos can be directly used for image interpretation, measurement, and thematic mapping, serving resource and environmental research, and can also be used to create various image maps and map updates.

● Gas Pipeline Inspection | Solution (Full Coverage Inspection)

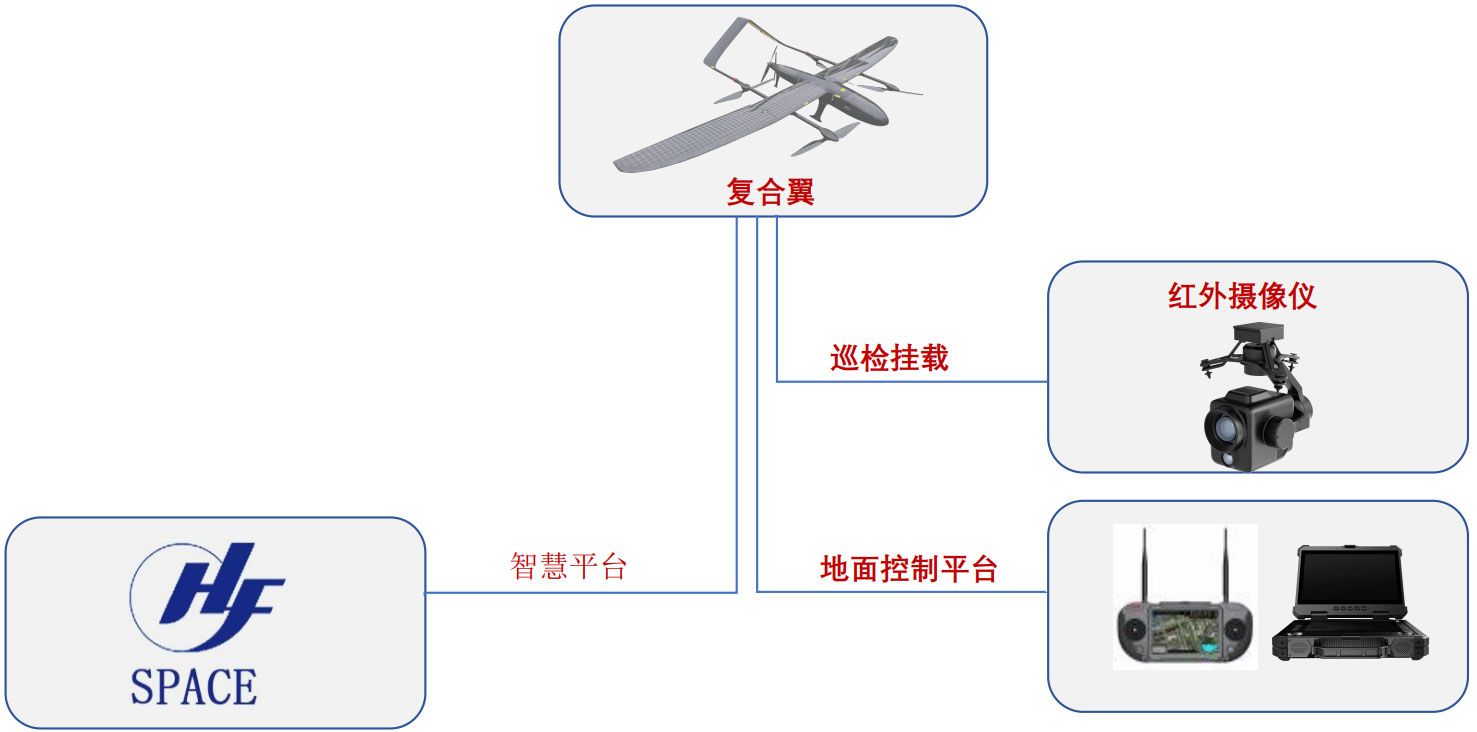

1. Adopt a solution combining a compound-wing drone and a multi-functional pod to achieve full-scene coverage of gas pipelines.

2. Preset pipeline inspection routes, automatically fly along the pipeline, clearly obtain ground image data of long-distance pipelines, and perform data analysis to achieve rapid inspection.

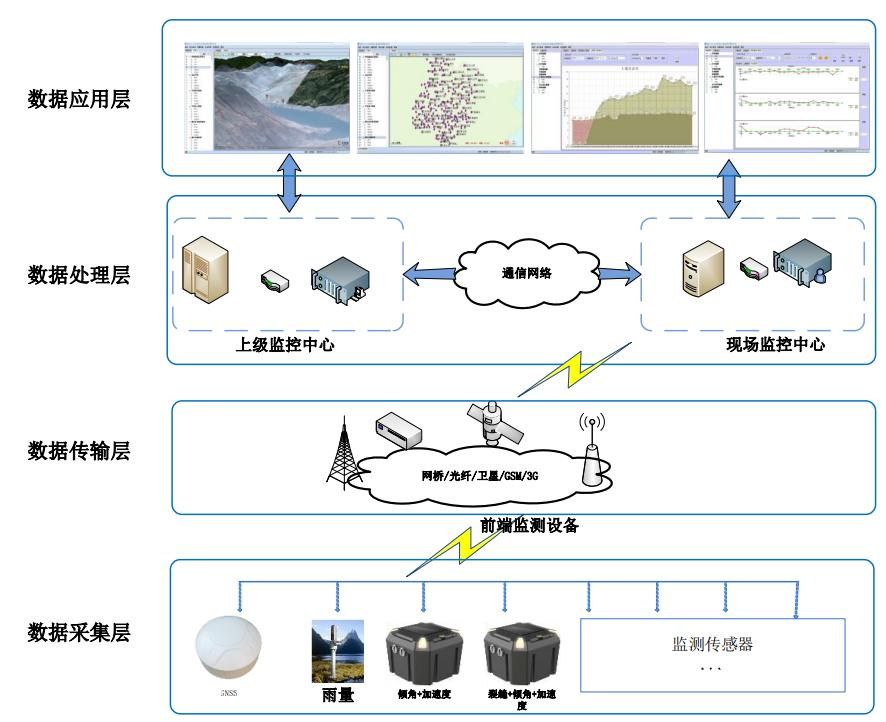

● Gas Pipeline Inspection | Solution (Fixed-Point Monitoring)

1. Implement fixed-point monitoring of geological hazard points and high-consequence areas using sensors and deformation monitoring equipment for all-weather monitoring.

2. Through intelligent monitoring equipment and an environmental monitoring cloud platform, the system can achieve automated monitoring and early warning. Data acquisition, processing, and analysis can be automatically completed without manual intervention, reducing maintenance costs, improving monitoring efficiency, and ensuring the timeliness and accuracy of warning information.

3. A solar power supply system provides green and sustainable energy for fixed-point monitoring and early warning. Through high-efficiency solar panels and energy storage devices, the system can maintain a stable power supply under various environmental conditions without relying on external power grids, enhancing the system's independence and reliability.

Equipment Configuration

● Gas Pipeline Inspection | Fixed-Point Monitoring Equipment

GNSS Automatic Ground Displacement Monitoring Station: Installed on a stable cement base, it monitors the three-dimensional displacement changes of the ground surface in real time, with high precision and stable operation under harsh environments.

Mud (Water) Level Monitoring Station: Uses a pole-mounted installation, monitors mud water level changes in real time, with high precision and early warning.

Tilting Bucket Rain Gauge Station: Uses a pole-mounted installation, accurately measures rainfall, records and transmits rainfall data.

Wireless Early Warning Broadcast Station: Uses a pole-mounted installation, promptly releases various early warning information.

Video Surveillance Equipment: Includes cameras and storage devices, with night vision capabilities, for real-time video surveillance of the monitoring area.

● Gas Pipeline Inspection | Fixed-Point Monitoring Equipment

Data Monitoring Center: Includes servers, computers, and monitors, analyzing and processing data from various monitoring devices, proposing corresponding solutions, and implementing and resolving them.

● Gas Pipeline Inspection | Full Coverage Inspection Equipment (Radius 80 km)

Scene Advantages:

1. Automatically conducts inspection operations according to the planned route

2. Automatically feeds back inspection results (suspicious personnel and equipment, illegal excavation, site encroachment, erosion and exposure, etc.)

3. Operation radius of 80 kilometers

4. Backend takes over drone for refined inspection

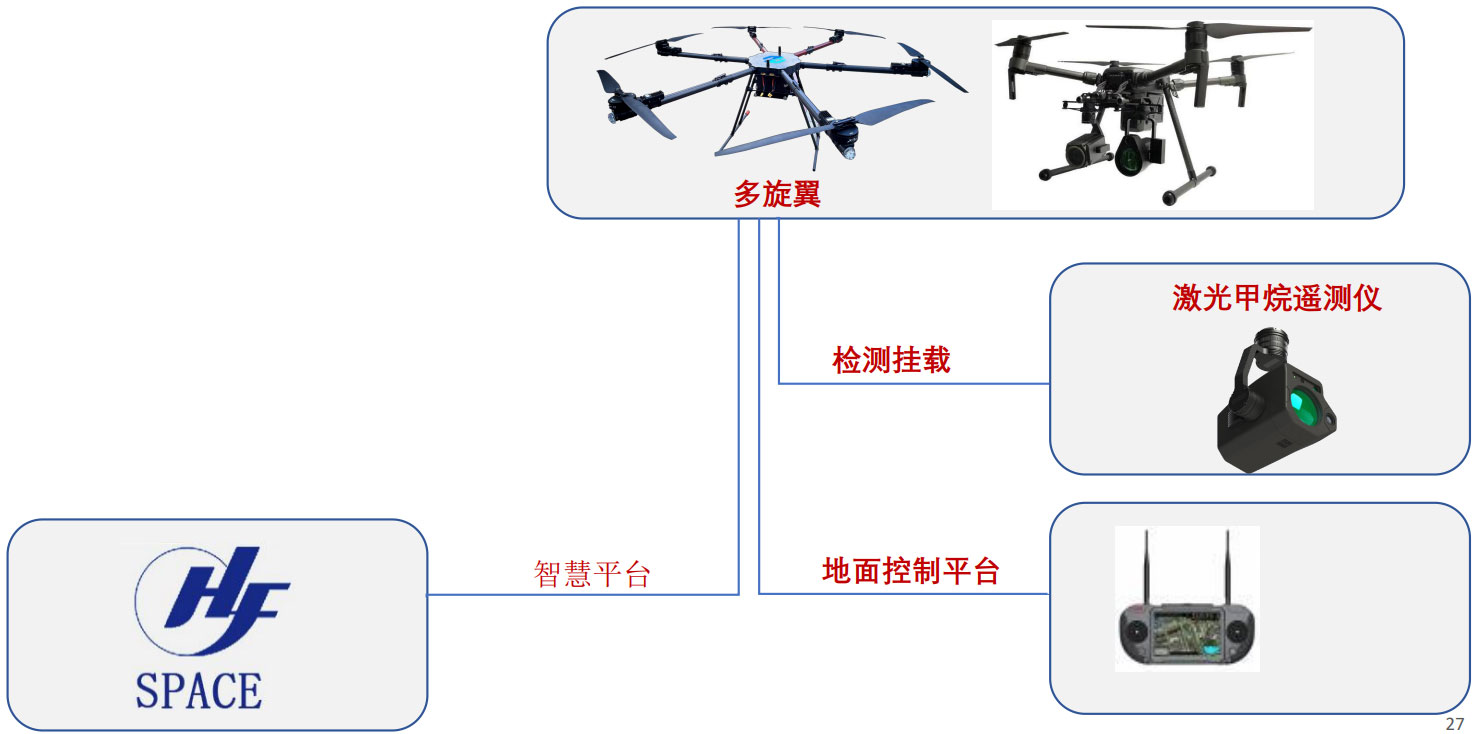

● Gas Pipeline Inspection | Optional Equipment (Leak Detection)

Scene Advantages:

1. Conduct precise inspections based on valve chamber leak alarms to locate leak points

2. Automatically feed back inspection results (leak point photos, coordinates, leak volume)

3. Operation radius of about 20 kilometers

Smart Environmental Protection - UAV Water Rescue Application Scenario Solution

Needs Analysis

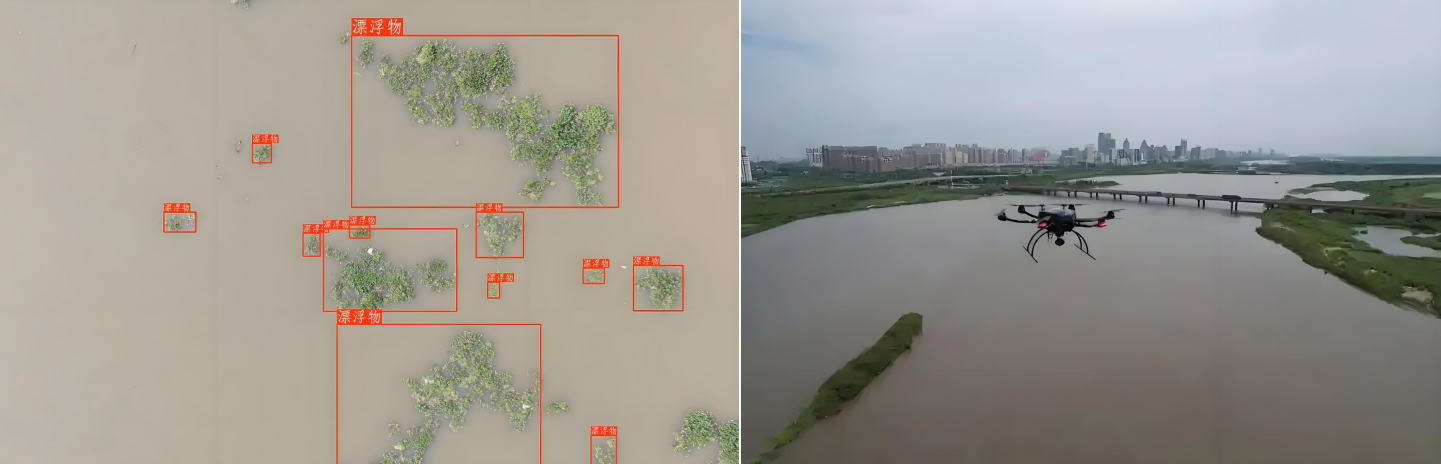

● Regular Inspection | Inspection Content

Rapid Search and Rescue and Positioning:Target recognition, multi-dimensional reconnaissance, etc.

Emergency Supplies Delivery and Support:Remote throwing, medical supplies transportation, etc.

Environmental Monitoring and Pollution Control:Water quality and pollution monitoring, hydrological data acquisition, etc.

Communication and collaborative work support:Emergency communication relay, cluster collaboration, etc.

● Regular Inspection | Equipment Configuration

I. Platform Construction

This system mainly includes an AI video intelligent analysis system (developing an AI model library, automatically identifying parameters such as crack width and rust area, quantifying damage, etc.), mobile video management and analysis, unmanned aerial vehicle video management and analysis by section, and radar data intelligent analysis. Through the construction of a command intelligence platform, it realizes task setting, route planning, automatic identification, risk warning data storage and processing, meeting the needs of water traffic congestion early warning, facility water area inspection, emergency command, and illegal evidence collection, etc.

II. BIM Information Input

Adopting a modular architecture, a basic application support platform is built, including BIM models, GIS data, BIM+GIS engine, BPM process engine, BI analysis tools, integrated communication system, unified identity authentication service, digital twin engine, simulation decision engine, vehicle-road collaboration engine, Beidou high-precision positioning service, mobile APP, etc., providing support for various businesses of SaaS (business application layer).

III. Building a 5G platform

Combining 5G network to transmit data in real time to the command center, and linking with the traffic signal system. Developing an event priority algorithm to automatically trigger emergency tasks (such as accident scene blockade, material delivery, etc.).

IV. Full coverage inspection equipment: UAV + nest