Intelligent Transportation

● Daily Inspection Service

A traffic police team launched a concentrated crackdown on drunk driving and other serious traffic violations, increasing the intensity of enforcement, fully playing a deterrent and warning role, preventing the occurrence of all kinds of traffic violations, preventing and reducing traffic accidents, and creating a safe and harmonious traffic environment. In addition, drones were used to assist police officers in handling drunk driving and other serious traffic violations. Utilizing advanced technologies such as wireless communication remote control, aerial hovering, image transmission, and GPS Navigator positioning, a pilot program was implemented, making traffic management and accident handling in the jurisdiction faster, more intuitive, and more efficient. During the Spring Festival, drone aerial photography was used to strengthen traffic management and accident handling on key road sections.

● Emergency Traffic Rescue

A major traffic accident on the G60 Shanghai-Kunming Expressway resulted in multiple children being injured, and the situation was urgent. The accident caused unusual road congestion, even requiring the use of a helicopter. A drone arrived at the scene 10 minutes before the helicopter, dropping off rescue supplies (medical kits, tourniquets), buying valuable time for the injured children's medical treatment.

● Scheme Value

☆ Low cost, quick and easy image acquisition

☆ Strong timeliness, rapid response

☆ Strong anti-interference ability of equipment

☆ Seamless docking with video surveillance system

☆ Strong mobility, good work continuity

☆ Less affected by climate and geographical conditions

☆ Much stronger video transmission capability

☆ Data sharing and co-viewing among multiple departments

● Smart Public Security Scheme ●

|

|

|

|

| Flight Platform | Pilot Task Management System | Drone Pilot | Intelligent system platform |

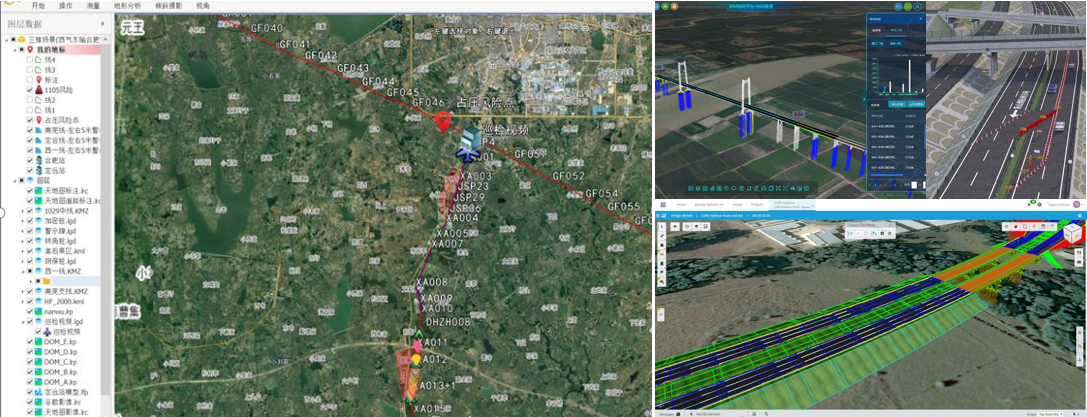

Qiandongnan Prefecture Expressway Intelligent Inspection Project

● Routine Inspection | Basic Situation

Inspection Scope:Expressways (road surface cracks, potholes, etc.), bridges (under bridges, cracks, pits, displacement, etc.), bridge piers (spray paint protection), slope inspection, tunnel inspection (top of the tunnel, road surface, etc.) infrastructure, violations, emergencies, rescue, command orthographic projection

Situation Analysis:Some sections are restricted or prohibited flight zones (prohibited flight zones: Huangping Airport, Liping Airport; restricted flight zones: high-speed rail lines and national key facilities)

Inspection Content:Automatic identification, early warning, platform construction

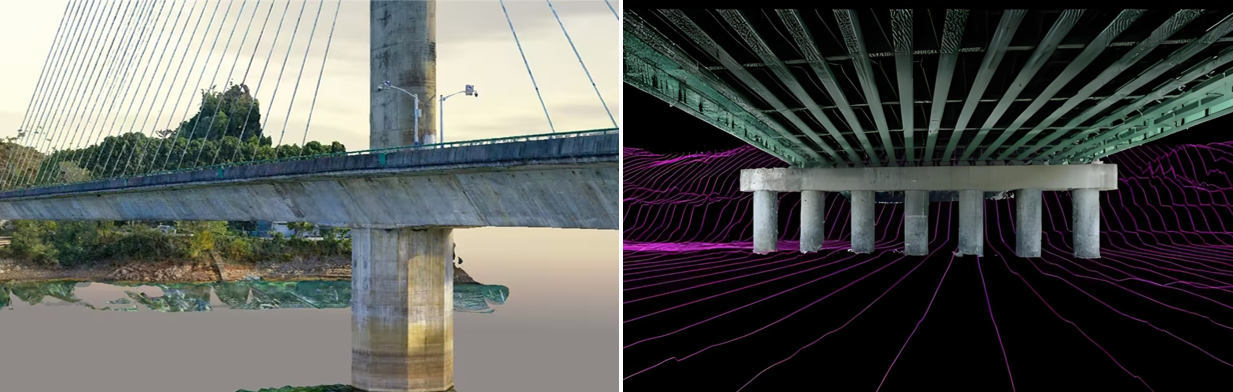

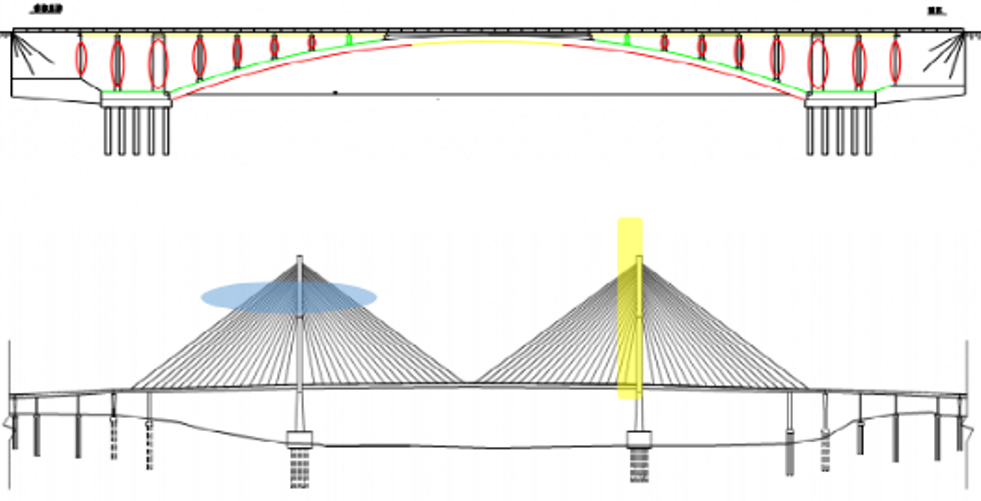

Bridge routine inspection mainly includes:Bridge deck system: bridge deck paving, bridge head boards, expansion joints, drainage system, guardrails, etc.; bearings; upper structure: main beams, main trusses, main arch rings, cross beams, main nodes, connecting pieces, etc.; lower structure: cap beams, pier bodies, abutment bodies, wing walls, cone slopes and riverbed scouring, etc.; other related facilities (lighting, electricity, electrical conduits, etc.) that affect the safe operation of the bridge.

● Routine Inspection | Inspection Content

Orthographic projection, expressway inspection and bridge pier painting

① Orthographic images; ② Bridge pier painting; ③ Expressway inspection;

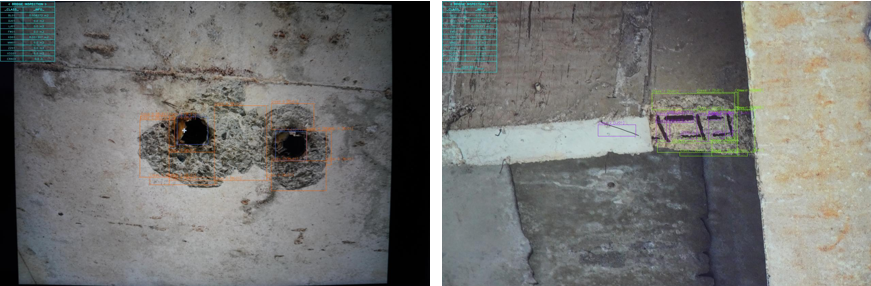

(Left) Intelligent bridge detection; (Right) Exposed reinforcement, spalling detection

(Left) Cavity, spalling detection; (Right) Exposed reinforcement, corner drop detection

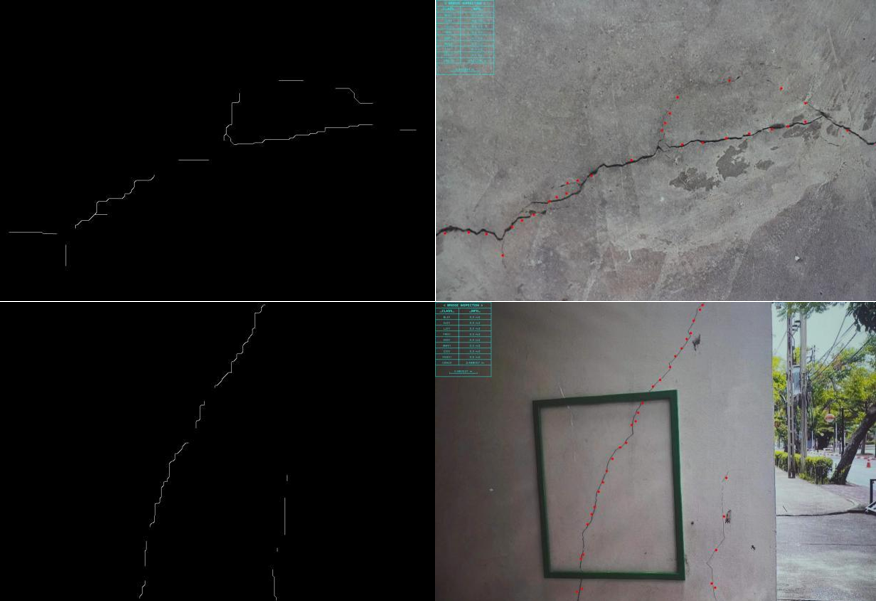

Crack detection

Bridge bearing inspection

Expressway slope inspection

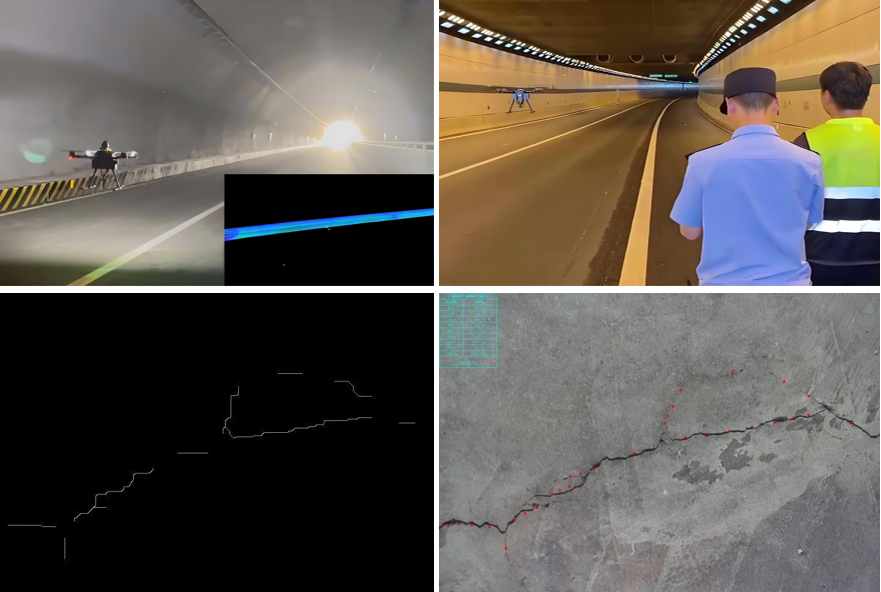

Tunnel inspection: inspection of tunnel cracks, road surface potholes, road surface cracks, etc.

Third-party damage: human and animal intrusion, damage from construction on both sides

Infrastructure inspection: streetlights, guardrails, road conditions, signs, monitoring, ETC gantries

Traffic guarantee: violation evidence collection, congestion early warning, weather information release

Emergency needs: accident handling, congestion relief, fault rescue

● Routine Inspection | Equipment Configuration

1. Platform Construction

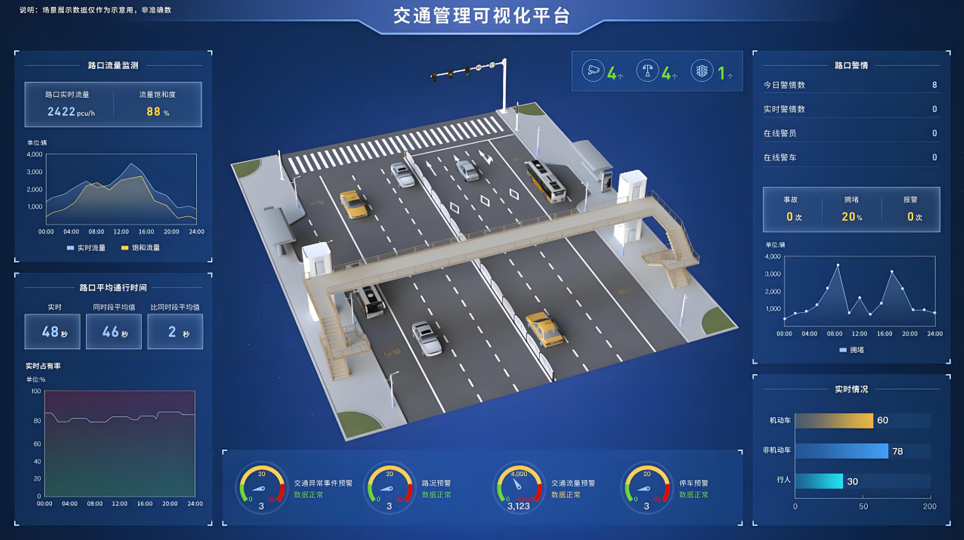

This system mainly includes an AI video intelligent analysis system (developing an AI model library, automatically identifying crack width, rust area, etc., quantifying damage, etc.), vehicle-mounted mobile video management and analysis, drone video management and analysis by section, and radar data intelligent analysis. Through the construction of a command intelligence platform, task setting, route planning, automatic identification, risk early warning data storage and processing are realized, meeting the needs of traffic congestion early warning, facility road surface inspection, emergency command, violation evidence collection, and traffic accident handling.

2. BIM Information Input

Using a modular architecture, a basic application support platform is built, constructing a BIM model (integrating data, generating a three-dimensional model and marking the location of defects, supporting construction simulation and maintenance decision-making), GIS data, BIM+GIS engine, BPM process engine, BI analysis tools, integrated communication system, unified identity authentication service, digital twin engine, simulation decision-making engine, vehicle-road collaboration engine, Beidou high-precision positioning service, mobile APP, etc., providing support for various businesses in the SaaS (business application layer).

3. Building a 5G Platform

Combining 5G network to transmit data in real time to the command center, coordinating the traffic signal system to optimize traffic flow. Developing an event priority algorithm to automatically trigger emergency tasks (such as accident scene blockade, material delivery, etc.).

● Routine Inspection | Data Acquisition Results

◆ High-definition materials

◆ Photos with coordinate information

◆ Precisely locate risk points (focus on identifying directional drilling and other third-party construction)

◆ Easy to trace back

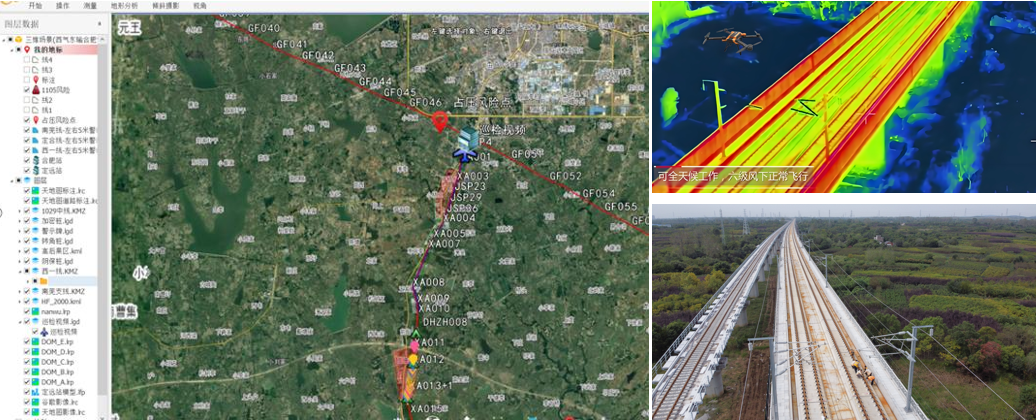

DJI Matrice 300 RTK drone, equipped with a high-definition camera (H20T), multispectral sensor, and LiDAR (L1), supports high-precision 3D data acquisition.

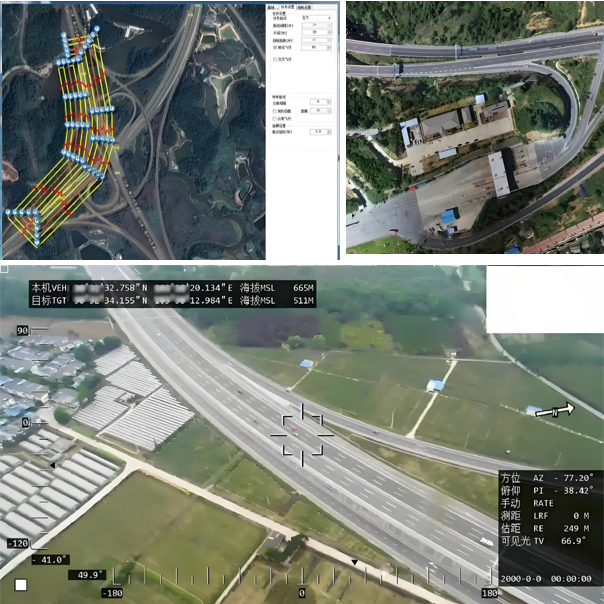

● Routine Inspection | Routine Inspection Mode

Thermal Imaging Detection

Drones can carry thermal imaging cameras at night for vehicle safety monitoring, road facility inspection, and emergency rescue.

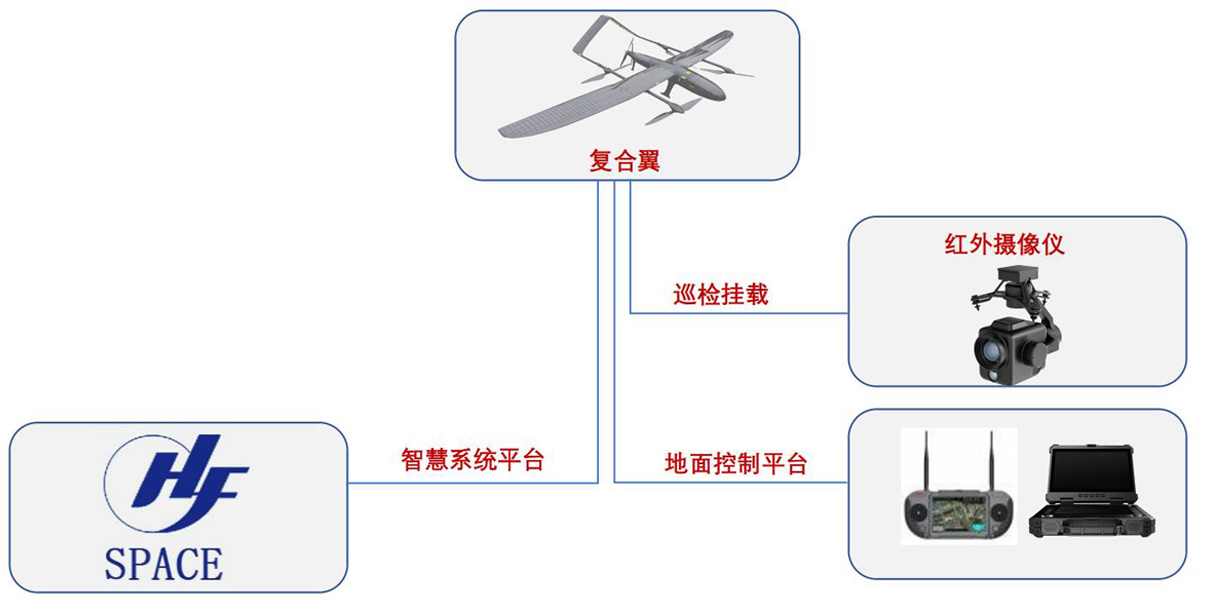

Long-range fixed-wing patrol

The collected high-definition photos have a resolution of up to 36 million pixels, with rich details of ground targets. The photos also include high-precision BeiDou coordinate information, allowing for precise positioning and distance measurement of risk targets in the photos later.

Bridge Inspection Plan

Using DJI Phantom 4 RTK drone for oblique photography and LiDAR scanning, with a resolution of 0.5cm/pixel and point cloud density ≥200 points/㎡. Integrating data based on BIM software (such as Revit, InfraWorks) to generate 3D models and mark the location of defects, supporting construction simulation and maintenance decision-making. Developing an AI model library to automatically identify parameters such as crack width and rust area, quantifying the damage level.

● Routine Inspection | Inspection Analysis

◆ Analysis and statistics of inspection process data and risk data (inspection results)

Inspection operation data is stored in the inspection business database and can be retrieved, queried, and statistically analyzed; risks found during daily highway patrols and various hidden danger information provided by informants are displayed and dynamically tracked on the visualization platform, achieving refined management; inspection process data and risk data are analyzed in real-time using big data and AI algorithms (such as YOLOv7) to automatically identify defects and generate inspection reports with an accuracy ≥95%, summarizing the patterns of risk occurrence at different inspection times, different regional locations, and different cycles, laying a data foundation for predictive risk prevention.

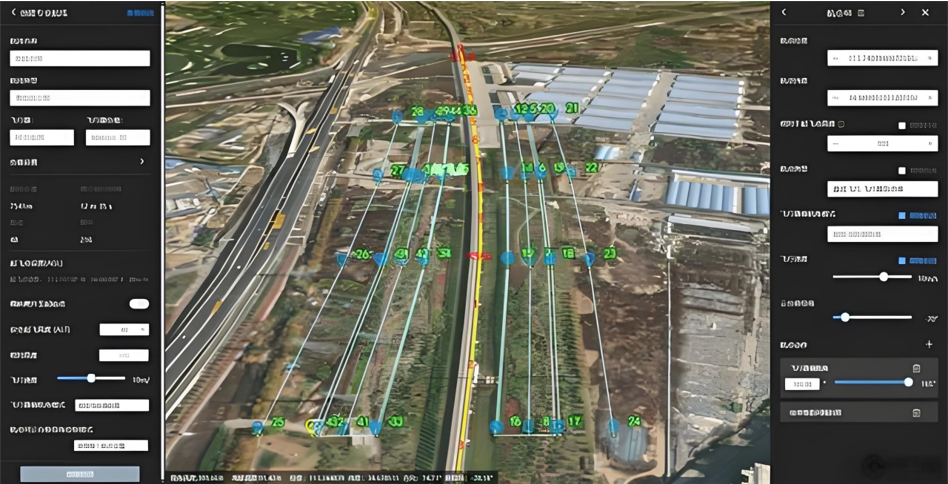

● Routine Inspection | Software System

◆ Highway Safety Visualization Management Platform (PSV) + 5G platform

◆ Unified presentation of all elements

Supports the presentation of various elements such as orthographic images, oblique photography 3D models, vectors, and point clouds on the same platform.

● Routine Inspection | Full Coverage Inspection Equipment (Radius 80km)

Scene Advantages:1. Automatically perform inspection operations according to the planned route; 2. Automatically feedback inspection results (personnel and equipment, illegal occupation, bridge cracks, road potholes, etc.); 3. Operation radius of 80 kilometers; 4. Backend fine-grained inspection of drone takeover;

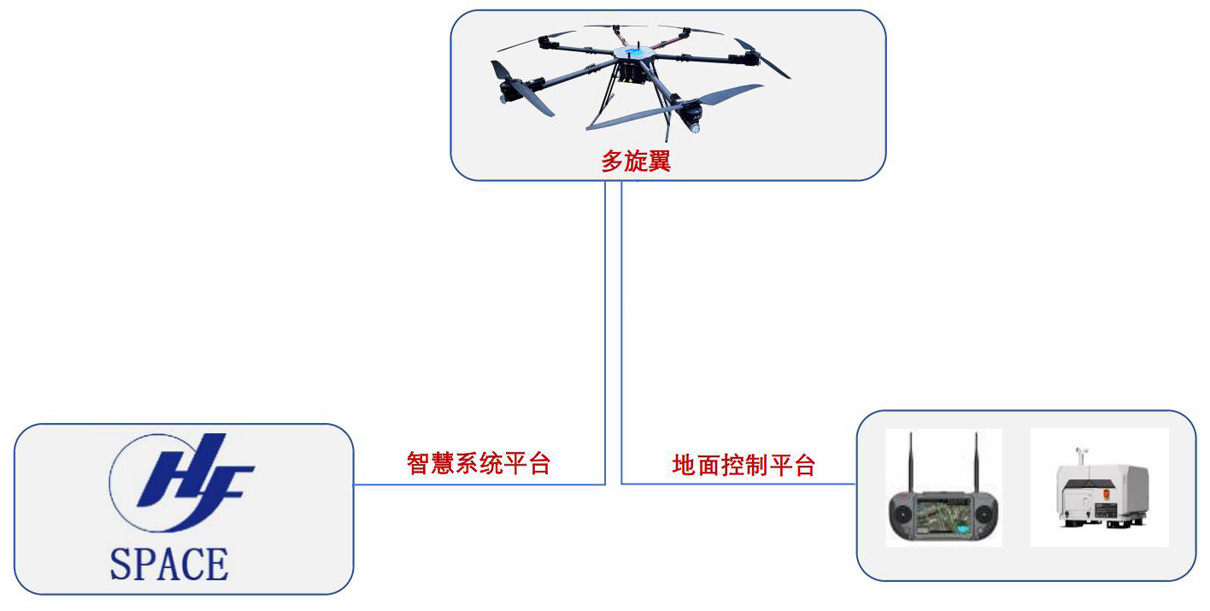

● Routine Inspection | Optional Equipment

Scene Advantages:1. Perform precise inspections based on alarm results from inspection results, finding cracks, exposed steel bars, and voids, etc.; 2. Automatically feedback inspection results (crack point photos, coordinates, crack width); 3. Operation radius of about 20 kilometers;

|

|

| DJI Matrice 300 RTK drone, equipped with high-definition cameras, multispectral sensors, and LiDAR, supports high-precision 3D data acquisition. | DJI Phantom 4 RTK drone for oblique photography and LiDAR scanning, with a resolution of 0.5cm/pixel and point cloud density ≥200 points/㎡. |

|

|

| DJI Mavic 3 Enterprise drone equipped with a thermal imaging lens, supports target recognition at night and in bad weather. Combines 5G network to transmit data in real-time to the command center, linking with the traffic signal system to optimize traffic flow. | DJI FlyCart 30 tethered drone, with a load capacity of 30kg, equipped with a high-pressure spray pump and anti-carbonization coating, supports continuous operation ≥2 hours; spray thickness error ≤0.05mm. Equipped with obstacle avoidance radar and redundant flight control system to ensure flight stability in high wind speeds (≤12m/s). |

|

|

| Self-developed 10-liter spray drone, with a load capacity of 10kg, equipped with a high-pressure spray pump and anti-carbonization coating, supports continuous operation ≥30 hours; spray thickness error ≤0.5mm. Equipped with obstacle avoidance radar system, etc. | Self-developed 20-liter spray drone, with a load capacity of 20kg, equipped with a high-pressure spray pump and anti-carbonization coating, supports continuous operation ≥30 hours; spray thickness error ≤0.5mm. Equipped with obstacle avoidance radar system, etc. |

Drone Intelligent Railway Inspection Plan

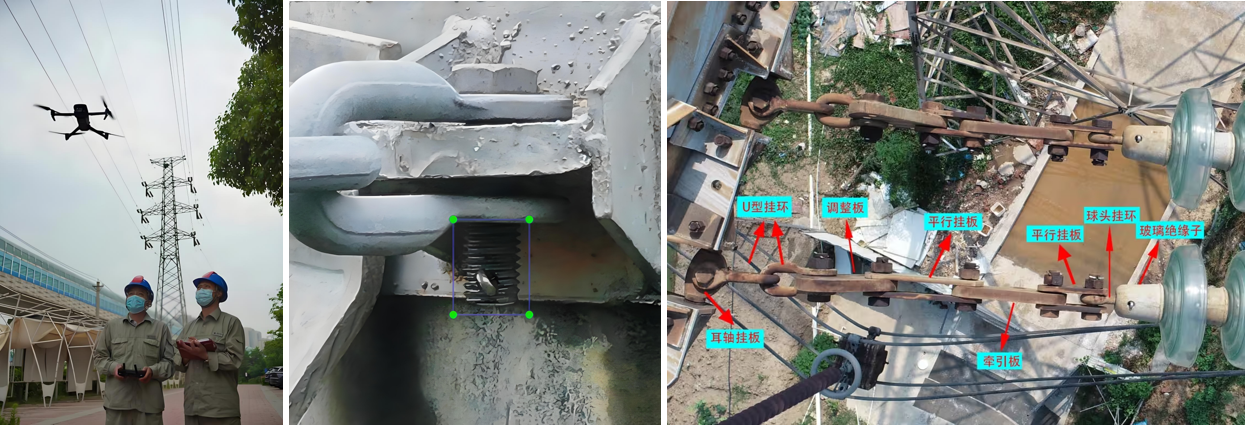

● Infrastructure Inspection | Inspection Content

◆ Track and Line Inspection:Track rust, loose bolts, missing pins, abnormal connection of wires and fittings, etc.

◆ Bridge and Tunnel Inspection:Inspect bridge bearings and tunnel water leakage, check for rockfall risks at tunnel entrances and exits, and conduct flood season surveys of mountains and water systems. Monitor tunnel structural safety and identify cracks or leakage hazards.

◆ Power Equipment Inspection:Take layer-by-layer photos of power towers, insulators, and line fittings, and analyze the images to identify defects (such as broken insulators and deformed fittings). The power supply section uses an unmanned aerial vehicle intelligent inspection system to achieve periodic and emergency tasks.

◆ Flood Control and Disaster Warning:Monitor flood control points and mountain flood sources along the railway line, check for safety hazards during the flood season, analyze mountain landslides and rockfall risks through remote sensing technology, and issue early warnings.

◆ Security and Emergency Inspection:Deploy drones to patrol key security areas and quickly deal with emergencies such as fires. Drones quickly survey accident sites and provide real-time image support for accident investigation.

◆ Fully Automatic Inspection System:Realize automatic takeoff of drones, execute tasks (photographing target objects and key parts) according to preset routes, and automatically return and upload and process data after completion.

◆ Data Processing and Decision Support:Utilizing AI and big data analysis to annotate defects, classify and statistically analyze collected images, and generate visualized reports to guide maintenance.

◆ Engineering Construction and Maintenance:During the construction phase, it is used for terrain mapping, construction progress tracking, and quality supervision; during the operation phase, it performs inspections of facilities such as catenaries and tracks. Training programs cover technologies such as UAV operation, mission planning, and 3D reconstruction to improve the efficiency of railway surveying and maintenance.

◆ Cross-field Collaboration:Integrating low-altitude economy and rail transit, the railway low-altitude intelligent inspection system achieves normalized operation.

◆ Efficiency Improvement:UAV inspection is more efficient than manual inspection, with a higher fault detection rate and the ability to cover areas inaccessible to humans.

◆ Safety Optimization:Reduces the safety risks of manual inspection (such as falls and traffic accidents) and supports operation in inclement weather.

● Routine Inspection | Equipment Configuration

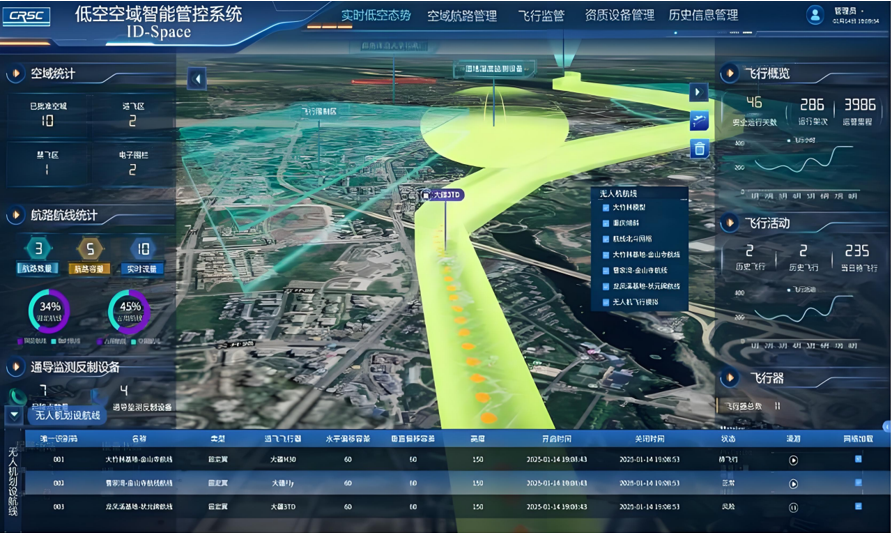

1. Platform Construction

This system mainly includes an AI video intelligent analysis system (developing an AI model library, automatically identifying crack width, rust area, etc., quantifying damage, etc.), vehicle-mounted mobile video management and analysis, drone video management and analysis by section, and radar data intelligent analysis. Through the construction of a command intelligence platform, task setting, route planning, automatic identification, risk early warning data storage and processing are realized, meeting the needs of traffic congestion early warning, facility road surface inspection, emergency command, violation evidence collection, and traffic accident handling.

2. BIM Information Input

Using a modular architecture, a basic application support platform is built, constructing a BIM model (integrating data, generating a three-dimensional model and marking the location of defects, supporting construction simulation and maintenance decision-making), GIS data, BIM+GIS engine, BPM process engine, BI analysis tools, integrated communication system, unified identity authentication service, digital twin engine, simulation decision-making engine, vehicle-road collaboration engine, Beidou high-precision positioning service, mobile APP, etc., providing support for various businesses in the SaaS (business application layer).

3. Building a 5G Platform

Combining 5G network to transmit data in real time to the command center, coordinating the traffic signal system to optimize traffic flow. Developing an event priority algorithm to automatically trigger emergency tasks (such as accident scene blockade, material delivery, etc.).

IV. UAV + Docking Station

UAV Highway Inspection Plan

● Highway Inspection | Inspection Content

Third-party impact: Human and animal intrusion, damage from construction on both sides

Infrastructure inspection: streetlights, guardrails, road conditions, signs, monitoring, ETC gantries

Traffic guarantee: violation evidence collection, congestion early warning, weather information release

Emergency needs: Accident handling, congestion relief, accident rescue

● Implementation Plan | Equipment Configuration

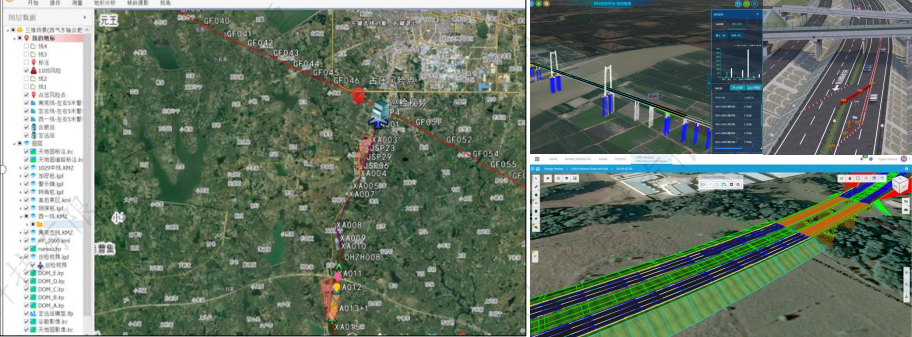

I. System Platform Construction

This system mainly includes AI video intelligent analysis system, vehicle-mounted mobile video management and analysis, UAV video management and section analysis, and radar data intelligent analysis.

Through the construction of a command intelligence platform, it realizes task setting, route planning, automatic identification, risk warning, data storage and processing, meeting the needs of traffic congestion warning, facility road surface inspection, emergency command, illegal evidence collection, and traffic accident handling.

2. BIM Information Input

Adopting a modular architecture, a basic application support platform is built, including BIM model, GIS data, BIM+GIS engine, BPM process engine, BI analysis tools, integrated communication system, unified identity authentication service, digital twin engine, simulation decision-making engine, vehicle-road collaboration engine, Beidou high-precision positioning service, and mobile APP, etc., providing support for various businesses in the SaaS (business application layer).

III. UAV + Docking Station